Case Studies

Delivering a full range of professional Solid Modelling, CAD and Engineering Design Services

Case Study: Structural Steel Main Entrance

This project dealt with working closely with a structural steel fabricator, to assist them in detailing and designing the steel and structural components of the entrance.

It is quite common nowadays that the main parties involved in the “built” industry do not always produce the detailed engineering drawings required by the structural steel fabricators.

The Architects produce the concept and overall details of construction, the Structural Engineer provides a technical report with a nomenclature of the steel sections and bolted joint requirements, with no detailed engineering drawings. At some point in the project the structural steelworker then must try to fabricate the components.

At this point, this is where Caddology Ltd can support the steelworker in taking the information from the Architect and Structural Engineer and decipher it into a pack and steel drawing with full detailed Bill of Material. This adds clarity to the process and provides bridges the gap in the whole process. All design works, models and detailed drawings were completed using Solidworks.

Case Study: 3D Modelling of Structural Concrete Staircase

We were contacted by a structural engineering practice to provide support in validating their detailed design for a large reinforced concrete structural staircase. They had the design intent all set out in 2D, but had no way to check the overall fit, form for the staircase as a whole.

Caddology Ltd were contacted to provide support in creating a full 3D model of all staircase segments and then completing the final general assembly model. Once all segments had been assembled the model provided a great insight into proving the design intent. We also provided an analysis on any interference issues.

In summary, the 3D model validated the 2D design intent. This was paramount to ensuring the large segments were correct, before going to mould manufacture and eventually casting the reinforced segments, de-risking the whole process. All design works, models and detailed drawings were completed using Solidworks.

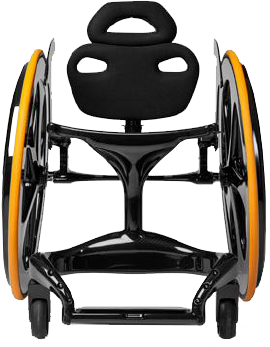

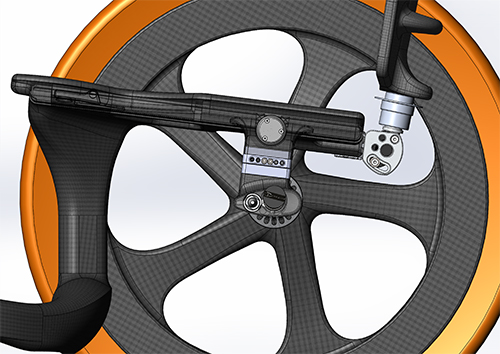

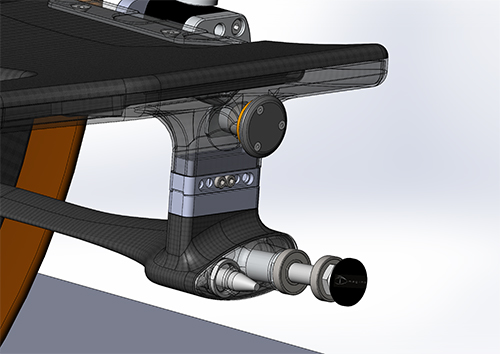

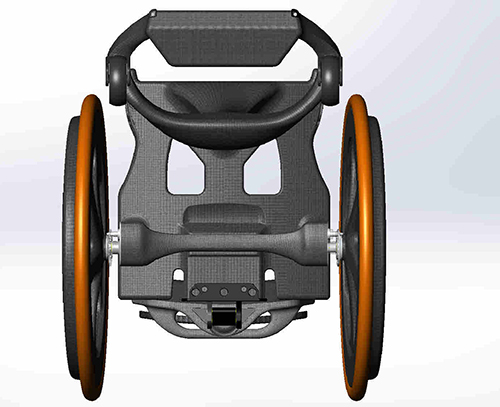

Case Study: A new kind of wheelchair

We were invited to help design a new, ‘high end’ lightweight carbon composite wheelchair. Our client already had ‘dumb’ CAD data, which they had used to produce a basic product design. We came in to provide a selection of composite mould tool designs, which would help the wheelchair adjust to suit the ergonomic requirements of its users.

Impressed with our work on the wheelchair design itself, we were subsequently hired by other composite manufactures for other project.

The end product was a fully ergonomic, lightweight wheelchair, with carbon composite parts and non-composite parts of high engineering-grade aluminium and titanium alloys. It’s a project we’ve been very proud to be involved with.